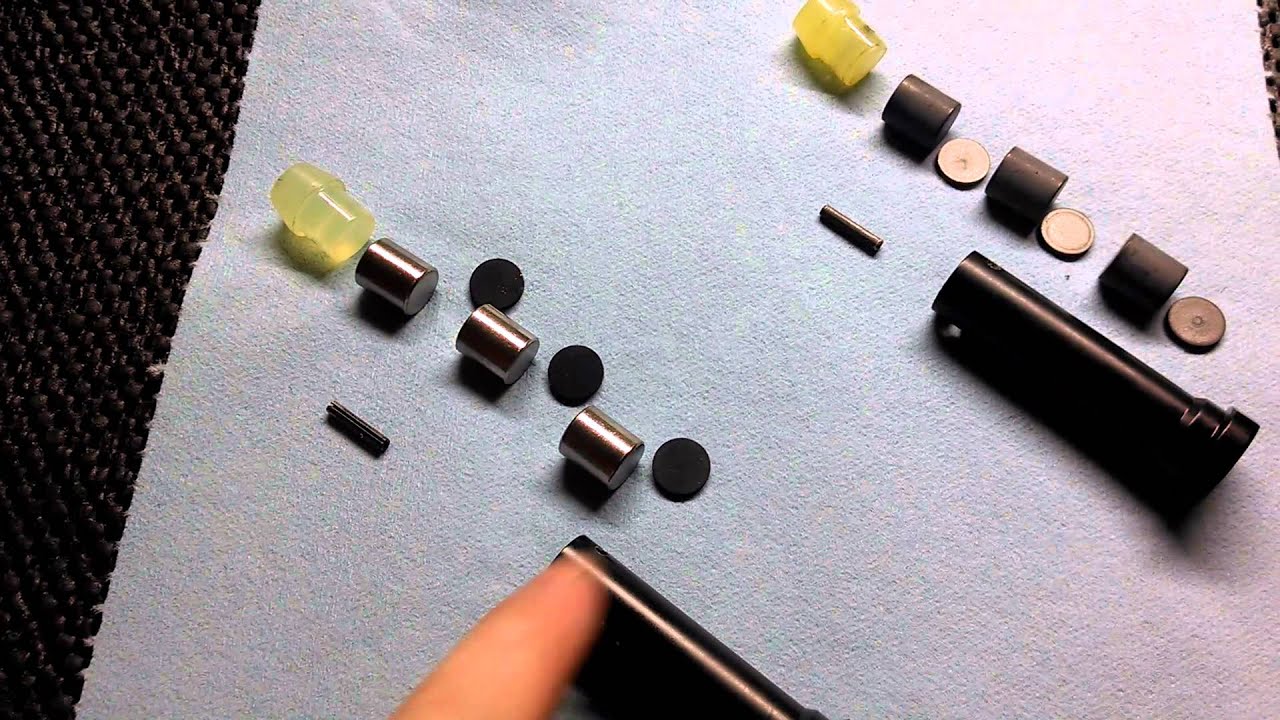

Some buffer tube manufacturers (such as V Seven Weapons, LMT and VLTOR) have developed finishes or precision grind the inside of the buffer tube that helps to reduce this by increasing lubricity and/or smoothness of the surface. Standard Rifle Spring – Measures 12.75” with 41 to 42 coilsīecause standard diameter springs rub the internal surface of the buffer tube, the AR platform is known to have a “twang” sound after firing each round.Standard Carbine Spring – Measures 10.5” with 37 to 39 coils.Most aftermarket springs use a spring tension weight that is +10% over the standard spring and they will be labeled as such. While it’s more common to “tune” a rifle by changing the buffer, different spring rates are another place where the rifle builder has choices. Both rifle and carbine springs have the same diameter, just different lengths. Illustration-cutaway of a standard bufferįor the most part, buffer springs are all fairly similar. While there is argument amongst some builders that the movement of the steel shot inside the buffer affects cycling, there are no real case studies known that show any pros/cons for the buffers that are made with the steel shot. Some manufacturers use “steel shot” inside their buffers to equate their buffer weights to the standard steel/tungsten specs above.There are also heavier buffers for pistol caliber carbines, but we'll leave that subject for another post in the near future.

– 5 steel weights + 1 steel spacer inside buffer

#H3 buffer weight how to

We will be covering how to tune your action and gas system in a future article.īelow are the different weights of carbine buffers available. These are not the only options by the way. When building a custom rifle, the variety of buffers and springs available allow the rifle builder options to optimize the gas delivery. Most off the shelf ARs are typically “over gassed” from the manufacturer to ensure reliability with various types of ammunition and operating conditions. Ultimately, other factors including barrel length, gas port size, gas tube length, dwell time, use of suppressor, etc…all affect the gas management. While the buffer and buffer spring are commonly used to “tune” a rifle, the rifle builder must recognize that the buffer and spring are only two mechanical components that affect the cyclic action. Most of the stocks on the market use a Mil-Spec carbine buffer tube and are adjustable for length of pull. Generally, fixed stocks use an A2 smooth buffer tube and adjustable stocks use a carbine buffer tube.

Carbine buffer weights are used with most collapsible stocks that utilize a carbine buffer tube. The extra length helps to fill the void in the longer A2 rifle buffer tube. Rifle length buffer weights are used when a standard A2 buffer tube is installed for a fixed stock.

The important headline here is that these two sizes are NOT interchangeable. While all dire AR rifles function similarly with this system, there are mainly two different sizes of buffers (rifle length and carbine length). When the buffer spring recoils, it pushes the buffer and bolt carrier forward, thus loading the next round of ammunition and closing the bolt for the next shot. The buffer is the contact point for the bolt carrier to move rearward within the buffer tube and the spring resides in the most aft position of the assembly. To begin, the buffer and buffer spring are housed within the buffer tube, and are crucial elements for the AR’s cyclic action. Now that we’ve covered the function and varieties of buffer tubes, we can drill down to the innards of the tube and focus on the buffer and buffer spring.

0 kommentar(er)

0 kommentar(er)